Why Multifuel burners?

- It gives the customer an opportunity to convert existing boilers into production units with renewable fuel at a lower capital cost than building a new boiler.

- The existing fuel is still available and can always be used as back up or topping up.

- When installing a new combustion system in an existing boiler the customer get a dual or triple fuel installation and can choose the most preferred fuel when he wants.

- The burners are operated in automatic and fast responding to load changes.

- The normal fuel are pellets and these have a high energy density compared to wet fuels, pellets can be stored at a small foot print, the flue gas flow is dry and the equipment is smaller than when firing wet fuels.

- Low emissions of NOx and CO.

- The availability is very high and maintenance costs are low

- Fast load response, similar to oil and gas burners.

- The split between powder/oil or powder/gas can be done independent from 0 –100%.

What type of boilers?

- The best boilers to convert are water tube boilers since they have a better shaped furnace.

- Fire tube boilers are possible to convert but the down rating can be quite large since these type of boilers are designed for a high thermal load.

What type of fuels?

- The burners can be designed for gas, liquid and powder fuel. All three if the customer requires this.

- The renewable fuels that can be used are biogas, bio oil and dry biomass milled to a fine powder. The limitations for powder are < 10% MC, particle distribution 100%< 1mm & 70% < 0,5mm.

- Different fuel types for multi fuel burners:–Powder: Wood, Agro, Peat, Bark & Coal

-Oil: HFO & Diesel

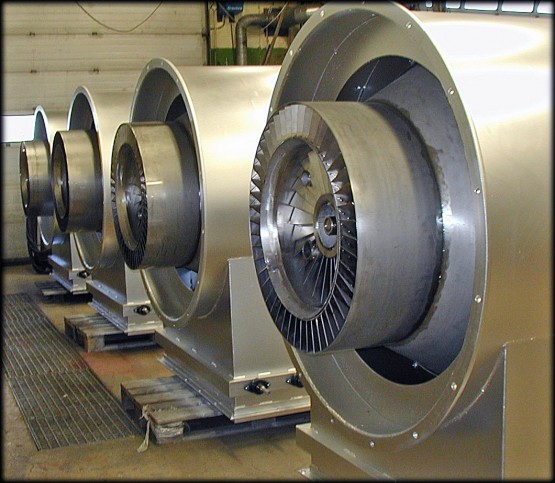

-Gas: Natural Gas, Propane & Process gas - Burner sizes 2 MW – 50 MW /burner.

Converting to WTS multifuel burner:

- Existing boilers and furnaces can be used.

- A conversion can normally be done fast and easy when replacing existing burners.

- Changing the burners can be done at an appropriate time with continued use of the original fuel.

- Powder handling can be completed with the burner in use and a transition can be made when powder is available.

- The original fuel is always available to 100% and can be used as a backup or for topping up.

- The plant is quickly started and quickly stopped with a turndown ratio of 1:4.

- For new built plants the boilers can be smaller and requires a smaller foot print than wet biomass boilers.

- No modifications are usually needed of buildings.

New equipment can be optimally placed on the site.